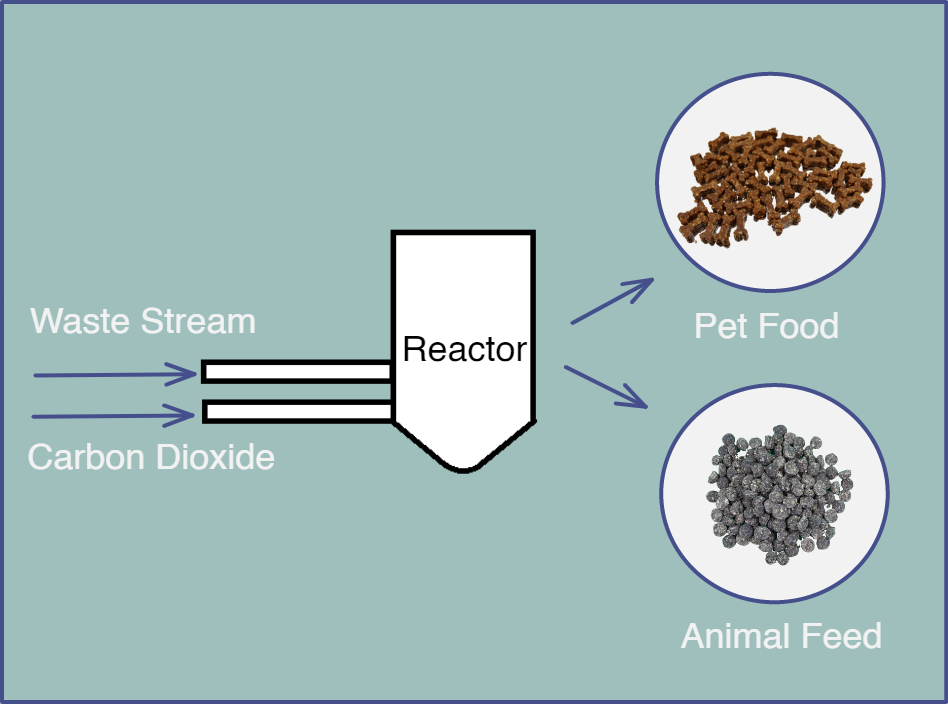

From spent recoverable based on the food and beverage industry, along with CO2 used as feedstock in the Protomix cycle which produces animal feed and pet food.

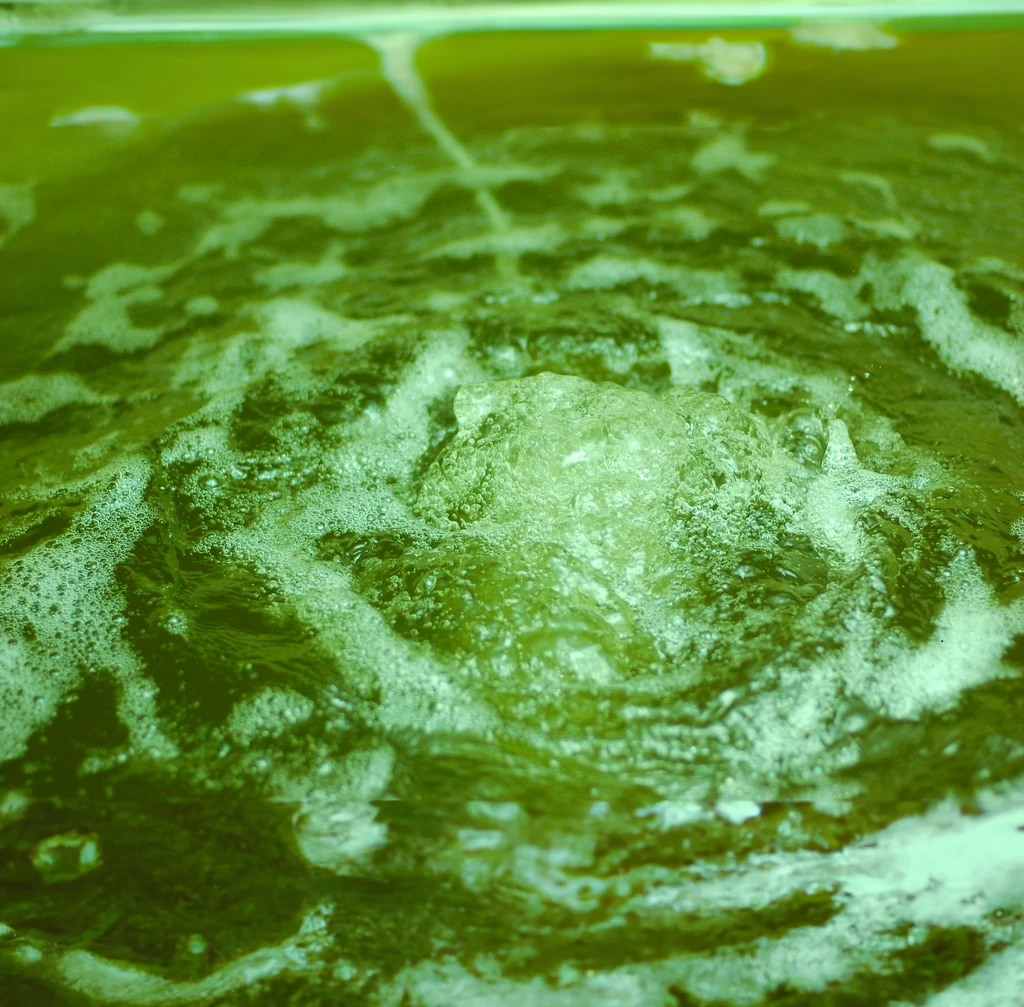

Protiomix has applied adaptive evolution techniques among other methods to develop novel consortia which grows rapidly on spent recoverable waste by utilising it as feedstock with combined CO2 uptake and sequestration. This consortia is highly versatile and has demonstrated 1.5 to 5-fold improvement compared to monocultures.

Our consortia is more resilient to external environment factors and feedstock variations.

Bioreactors are TOTEX intensive resulting in high start-up, production, and downstream costs. This increases costs for other systems. Reepel has collapsed production cost using novel mass transfer systems and downstream production andproduct extraction technologies. These have shown synergistic compatibility with our consortia based systems, wherein preliminary studies have showcased nearly 5-fold production improvement over monocultures. Reepel's advanced bioreactors have the lowest OPEX and and highest yield for a given CAPEX.

A combination of the biological engineering and process engineering has resulted in Protiomix being able to produce animal feed and pet food at competitive pricing whilst sequestering CO2, remediation waste stream and provide localised on-site 24/7 production. This enables us to be economical for our customers whilst offering a truly sustainable solution.